|

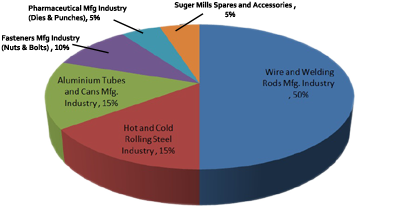

Market demands, Industry volatility & High expectations at low cost have increased in recent years causes profitability, quality, and service levels. The standard practice had been for BMW to focus on the goals to achieve these objects. BMW felt that even development in toolings is needed in order to provide improved output. |